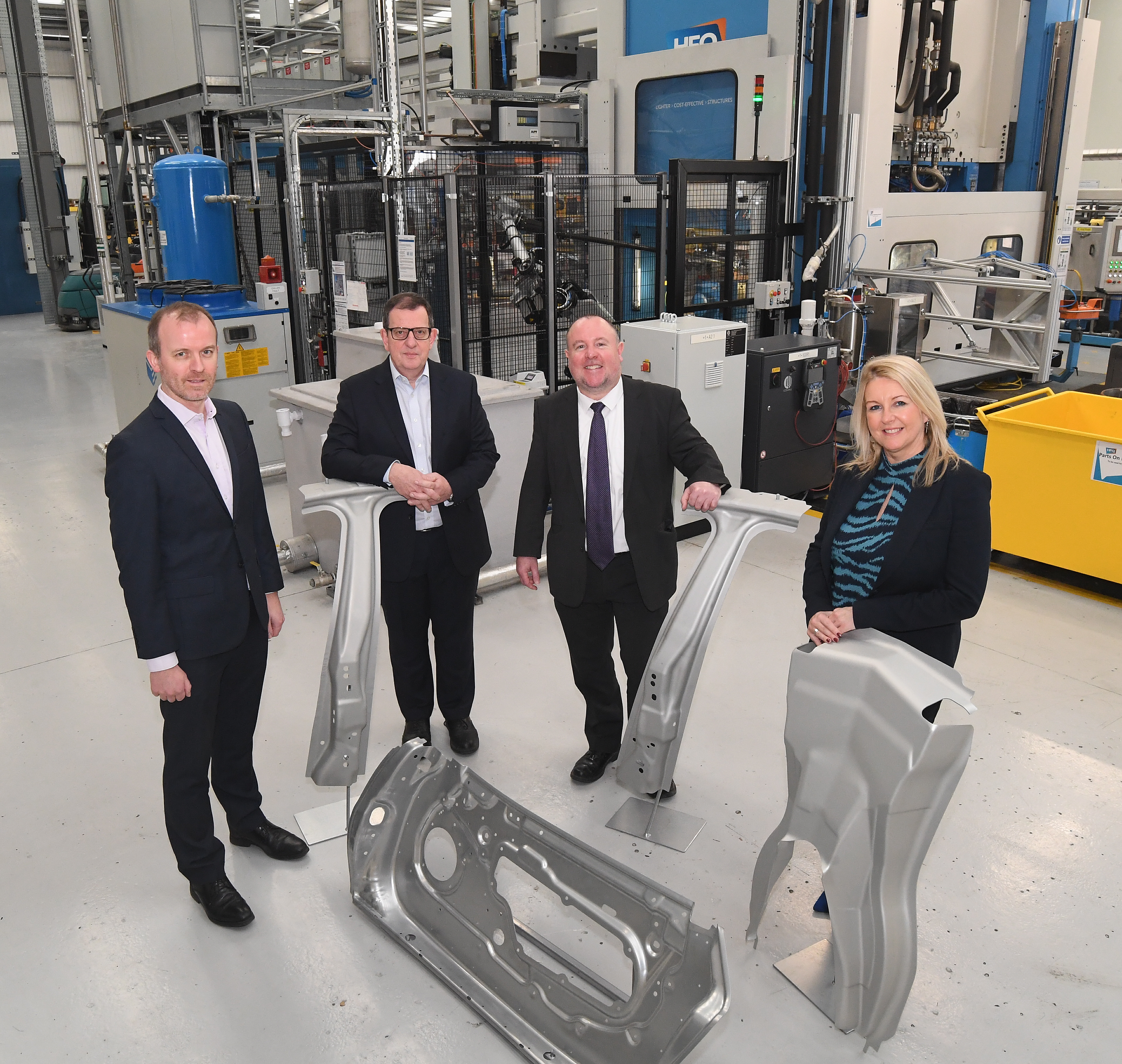

Coventry-based Impression Technologies was established in January 2013 and is the world’s first producer of Hot Form Quench® (HFQ)-produced parts for the automotive sector. The company is the exclusive commercialisation route for HFQ technology to all global markets.

Impression Technologies has been instrumental in developing HFQ Technology, which is revolutionising the exploitation of aluminium for light-weighting and complex shapes. The company also provides knowledge and expertise to support HFQ Technology.

Impression Technologies offers a fully tailored service according to engineering needs from concept to production.

The Challenge

Impression Technologies’ HFQ Technology forms hot aluminium blanks at high speed. The press tool surfaces require regular lubrication to ensure the consistent forming of the hot aluminium sheet to meet part requirements.

Over the course of 18 months, Impression Technologies developed a bespoke lubricant that was able to cope with the extreme temperatures of the HFQ process. The application of this lubricant had been carried out manually. Though effective, this process was not as efficient as applying lubrication via a robot and was an obvious bottle-neck for high volume production.

In order to meet the growing demand of HFQ technology, gain valuable knowledge and boost production, Impression Technologies needed to acquire robotic technology that would eradicate the need for the manual application of lubricant.

The Solution

Impression Technologies secured £37,800 in grant funding for a robot system from the Coventry and Warwickshire Business Support Programme, which is part funded by the European Regional Development Fund (ERDF). The company then issued a request for offer (RFO) for the robot on the CWLEP Growth Hub website.

Through its extensive range of regional business links, the CWLEP Growth Hub was able to alert Rugby-based robotics COMAU UK about the RFO. Following a competitive bidding process, Impression Technologies awarded the contract to COMAU UK.

The Result

Since acquiring the robot, Impression Technologies has been able to ramp up and double output thereby meeting increasing demand. The state-of-the-art technologyhas also helped to future-proof the

company in what is a fast-paced and highly competitive sector.

Simon Griffiths, Plant Director from Impression Technologies said “The company has experienced tremendous growth over the last 18 months and the robot was vital in helping us continue in this direction. “Acquiring the robot has enabled us to meet rising demand by ramping up production of aluminium parts through our HFQ technology. “We are very grateful to the CWLEP Growth Hub for supporting us in the acquisition of the robot. It was also very pleasing to be able to work with another Coventry and Warwickshire based company in COMAU UK.”

Client testimonials

GET IN TOUCH

Local office: 0300 060 3747

Email: support@cwgrowthhub.co.uk

About

Part of the Government-supported growth hub network